Factory seam duplication is a specialized auto body repair technique creating exact vehicle seam copies for structural integrity and crash safety. By examining original seams, taking measurements, and using advanced technology, shops manufacture new components that perfectly replicate the originals. This method enhances safety ratings, reduces costs, and enables more effective dent removal, significantly improving overall vehicle safety and facilitating design adjustments post-collision. Mitigating risks through best practices and integrating AI/machine learning can further enhance factory seam duplication processes.

Factory seam duplication, a process that replicates vehicle seams for testing, plays a critical role in crash safety ratings. This methodic replication aims to mimic real-world conditions, enhancing the accuracy of impact assessments. However, inaccurate or incomplete duplications can introduce risks, leading to misleading safety ratings. This article delves into the factory seam duplication process, its impact on crash testing, and explores best practices along with emerging technologies to mitigate potential risks, ensuring safer vehicles for all.

- Understanding Factory Seam Duplication Process

- Impact on Crash Testing and Safety Ratings

- Mitigating Risks: Best Practices and Future Technologies

Understanding Factory Seam Duplication Process

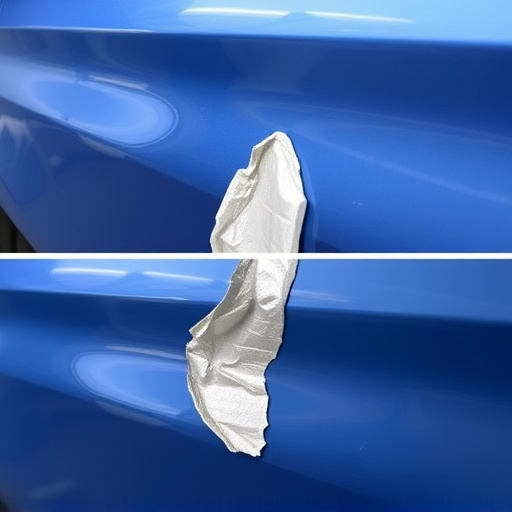

Factory seam duplication is a precision process that involves creating exact copies of vehicle seams, typically for repair or replacement purposes. It’s a specialized technique employed by auto body shops to ensure structural integrity and crash safety. The process begins with meticulous examination of the original seams, taking measurements and using advanced technology to capture every detail. This data is then utilized to manufacture new seam components that perfectly mimic the originals.

This method is especially valuable in situations where replacing an entire panel is costly or impractical. Auto body shops can repair specific damaged areas by duplicating the seamless design, maintaining the vehicle’s structural strength and enhancing its crash safety rating. Factory seam duplication offers a reliable solution for scratch repair and restoration, ensuring that vehicles return to their pre-incident condition while adhering to stringent safety standards.

Impact on Crash Testing and Safety Ratings

The impact of factory seam duplication on crash testing is significant. This process, which involves creating exact replicas of car bodywork seams during manufacturing, allows for more precise and realistic simulation of potential collisions in safety ratings tests. By duplicating the original seams, engineers can better assess how a vehicle will perform under extreme stress, providing a clearer understanding of its crashworthiness.

This advancement in car bodywork preparation enables collision centers to conduct more accurate dent removal and repair techniques, ensuring that the vehicle’s structural integrity is maintained even after minor accidents. As a result, factory seam duplication plays a pivotal role in enhancing overall safety ratings by allowing for better-informed design adjustments and more effective post-collision repairs.

Mitigating Risks: Best Practices and Future Technologies

Mitigating risks associated with factory seam duplication is a critical aspect of enhancing crash safety ratings. Best practices involve meticulous quality control during the manufacturing process to ensure precise duplicity. Advanced technologies, such as 3D printing and robotic welding systems, can significantly reduce human error, improving consistency in replicates. These innovations not only enhance structural integrity but also contribute to safer vehicle designs.

Looking ahead, future technologies like artificial intelligence (AI) and machine learning are poised to revolutionize auto repair and maintenance. AI-driven systems can analyze vast data sets from accidents, identifying weak points and potential areas of improvement in seam duplication processes. Integrating these advancements promises even higher safety standards, making auto repair near me more efficient and effective while also addressing concerns related to scratch repair and overall vehicle upkeep.

Factory seam duplication, while enhancing structural integrity, can significantly impact crash safety ratings if not properly managed. Understanding the process and its effects on crash testing is crucial for automakers to ensure vehicle safety. By adopting best practices and exploring future technologies that mitigate risks, the industry can optimize factory seam duplication, achieving both strength and safety without compromise.