Factory seam duplication is a critical technique in automotive manufacturing and collision repair that replicates original seams on vehicle panels, ensuring consistent material behavior and predictable NVH performance. This process maintains structural integrity, aesthetic similarity, and overall quality during car dent repair and auto body restoration, ultimately providing drivers with a quiet, comfortable, and safe driving experience. Best practices for factory seam duplication, requiring advanced equipment and trained personnel, enhance NVH control in automotive body shops by precisely duplicating seams while maintaining original dimensions and quality.

Factory seam duplication is a critical technique in the automotive industry, playing a pivotal role in achieving Noise, Vibration, and Harshness (NVH) control standards. This process ensures seamless joints between components, reducing unwanted noise and vibrations that can negatively impact vehicle comfort and performance. By duplicating factory seams, manufacturers can maintain consistency, enhance quality control, and meet stringent NVH regulations. In this article, we explore the fundamentals of factory seam duplication and its strategic implementation to optimize NVH control.

- Understanding Factory Seam Duplication: A Foundation for NVH Control

- The Role of Seam Duplication in Achieving Noise, Vibration, and Harshness (NVH) Standards

- Best Practices for Implementing Factory Seam Duplication to Enhance NVH Control Effectiveness

Understanding Factory Seam Duplication: A Foundation for NVH Control

Factory seam duplication is a critical process that forms the foundation for effective Noise, Vibration, and Harshness (NVH) control in automotive manufacturing. By precisely duplicating the factory-applied seams on vehicle panels, this technique ensures consistent and controlled material behavior during assembly and service life. This method replicates the original manufacturing processes, allowing for better prediction of NVH performance across the entire fleet.

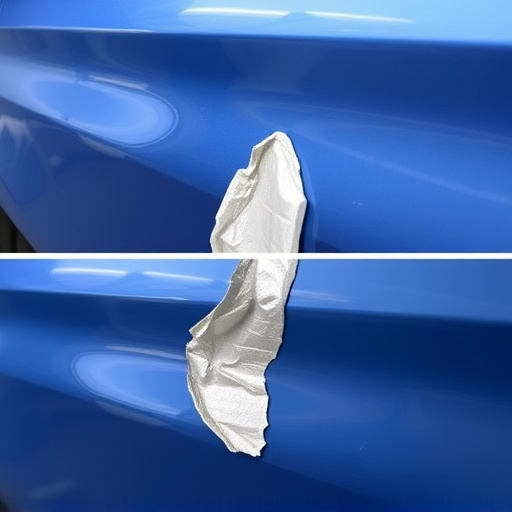

In car dent repair and auto body restoration scenarios, understanding factory seam duplication is paramount. Vehicle dent repair often involves replacing or repairing panels with new ones that must seamlessly integrate into the existing structure. Duplicating these seams ensures not only aesthetic similarity but also maintains the structural integrity and NVH performance expected by vehicle owners. This meticulous approach to replication contributes to the overall quality of auto body restoration, ensuring a quiet, comfortable, and safe driving experience.

The Role of Seam Duplication in Achieving Noise, Vibration, and Harshness (NVH) Standards

Factory seam duplication plays a pivotal role in achieving Noise, Vibration, and Harshness (NVH) standards in automotive manufacturing. By precisely duplicating seams on car bodies during the collision repair or car paint services process, manufacturers can ensure consistent and seamless joint integrity. This meticulous technique minimizes the potential for vibrations and noise that may arise from uneven or misaligned seams, which is crucial for meeting stringent NVH control requirements.

In the world of car body repair, factory seam duplication acts as a game-changer. It allows technicians to replicate the original vehicle’s construction, fostering a harmonious blend of aesthetics and functionality. This attention to detail not only enhances the overall quality of repairs but also contributes significantly to the vehicle’s overall NVH performance, ensuring a quieter, smoother ride for folks navigating bustling city streets or winding highways.

Best Practices for Implementing Factory Seam Duplication to Enhance NVH Control Effectiveness

Implementing best practices for factory seam duplication is a strategic move to significantly enhance NVH control effectiveness in automotive body shops and vehicle body repair processes. To start, achieving precise and consistent duplication requires advanced equipment and trained personnel. Utilizing specialized machines ensures seamless (no pun intended) replication of seams, maintaining the original dimensions and quality. This meticulous approach sets the foundation for effective noise and vibration reduction.

Moreover, integrating factory seam duplication into existing workflows should be systematic. It involves coordinating with designers, engineers, and manufacturers to ensure seamless integration. Standardizing processes across different automotive repair shops enhances consistency in seam duplication, which is vital for achieving uniform NVH performance standards. Regular calibration and maintenance of equipment are also crucial, as they guarantee accuracy over time, especially when dealing with intricate vehicle body parts.

Factory seam duplication plays a pivotal role in achieving Noise, Vibration, and Harshness (NVH) control standards. By replicating seams precisely during manufacturing, this technique significantly reduces unwanted noise and vibrations, enhancing vehicle comfort and performance. Adhering to best practices, as outlined in this article, ensures the effectiveness of factory seam duplication in meeting stringent NVH regulations, ultimately contributing to a superior driving experience.