Factory seam duplication is a cutting-edge process that creates precise copies of seams on aluminum and mixed-material car bodies, enhancing structural integrity and aesthetics in industries like automotive repair. This method involves meticulous scanning, digital blueprint creation using 3D printing or precision machining, and strict quality control to achieve flawless results matching original equipment standards. By automating this technique, manufacturers improve production efficiency, reduce costs, and deliver superior restoration outcomes for diverse car body materials, particularly lightweight aluminum alloys.

Factory seam duplication is a cutting-edge process transforming manufacturing, especially for aluminum and mixed-material bodies. This technique replicates complex seams precisely, enhancing structural integrity and design flexibility. In this article, we explore the process overview of factory seam duplication, delve into its significant advantages, and uncover best practices for successful implementation. Discover how this innovation is revolutionizing production efficiency and quality control.

- Understanding Factory Seam Duplication: A Process Overview

- The Benefits of Seam Duplication for Aluminum and Mixed-Material Bodies

- Best Practices and Considerations in Implementing Seam Duplication

Understanding Factory Seam Duplication: A Process Overview

Factory seam duplication is a specialized process that involves creating precise copies of seams found on aluminum and mixed-material bodies. This advanced technique is crucial for industries such as automotive, where achieving flawless replication is essential for maintaining structural integrity and aesthetic appeal. By understanding factory seam duplication, professionals in car scratch repair, auto dent repair, and auto body painting can better appreciate its significance in ensuring high-quality finishes.

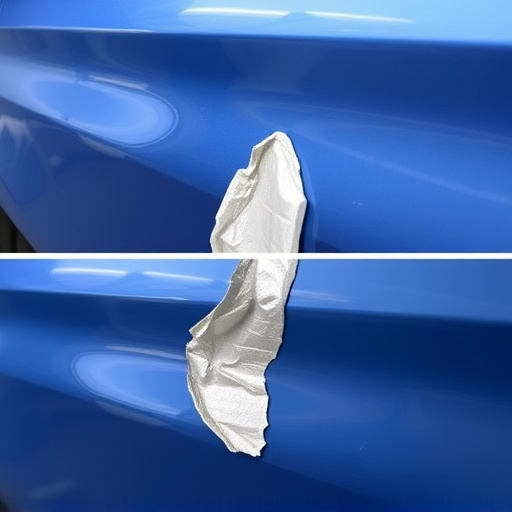

The process begins with meticulous examination of the original seams, breaking down their complex geometry into manageable components. Advanced scanning technologies are then employed to capture every detail, from contour lines to material compositions. These digital blueprints serve as guides for creating replicas using advanced manufacturing techniques, such as 3D printing or precision machining. The end result is a seamless duplicate that mirrors the original, ready to be integrated into auto body replacement parts, ensuring a flawless finish in auto dent repair and auto body painting projects.

The Benefits of Seam Duplication for Aluminum and Mixed-Material Bodies

Factory seam duplication offers significant advantages for both aluminum and mixed-material bodies, enhancing structural integrity and aesthetic appeal across various industries. By precisely duplicating seams, manufacturers can achieve seamless (pun intended) integration of different materials, ensuring strength and durability in automotive applications, from tire services to collision repair. This technique is particularly valuable when working with lightweight aluminum alloys, where maintaining structural rigidity while reducing weight is paramount.

Moreover, seamless duplication allows for improved production efficiency. Automating the process streamlines manufacturing workflows, enabling faster turnaround times and reduced costs. In the realm of auto maintenance and collision repair, this translates to quicker vehicle restoration and enhanced customer satisfaction. Factory-level precision ensures that every replicated seam aligns perfectly, resulting in a flawless finish that rivals original equipment.

Best Practices and Considerations in Implementing Seam Duplication

Implementing factory seam duplication for aluminum and mixed-material bodies requires a meticulous approach to ensure optimal results in car body restoration processes. Firstly, understanding the unique characteristics of each material is key; aluminum, for instance, demands precise techniques due to its tendency to distort or stretch upon impact. A well-equipped collision center should invest in advanced machinery capable of handling both metal and composite materials effectively. This includes state-of-the-art laser scanners and 3D printing technologies, which enable accurate measurements and seamless duplication of complex body panels.

Best practices also emphasize the importance of pre-treatment and post-processing. Proper surface preparation ensures that the duplicated seams blend seamlessly with the existing body. Additionally, training technicians on the latest methods for car dent repair techniques specific to factory seam duplication is vital. This ensures consistency, precision, and a final product that meets or exceeds original equipment manufacturer standards, resulting in superior quality car body restoration.

Factory seam duplication is a game-changing process that enhances production efficiency, especially for complex aluminum and mixed-material bodies. By accurately replicating seams, manufacturers can achieve superior product quality, reduce waste, and streamline assembly lines. Implementing best practices, including thorough material understanding and precise machinery calibration, ensures successful integration into existing manufacturing flows. This advanced technique promises to revolutionize the industry, offering both cost savings and improved product consistency.