Factory seam duplication is a vital automotive manufacturing process that replicates seams on roof and floor panels, ensuring structural integrity and aesthetic consistency. Advanced technologies like CAD software, robotic welding, laser cutting, and advanced painting systems streamline production, reduce costs, and improve quality control. This technique is crucial for post-collision repairs, preventing water damage, and fostering efficient vehicle restoration processes. Despite challenges with specialized equipment and skilled labor, the increasing demand for cost-effective restoration drives promising future prospects for factory seam duplication.

Factory seam duplication is a cutting-edge technique revolutionizing the manufacturing of roof and floor panels. This process precisely replicates intricate seam patterns, ensuring structural integrity and aesthetic uniformity across entire panel surfaces.

This article delves into the intricacies of factory seam duplication, exploring its understanding, underlying technologies, and multifaceted benefits. We also analyze challenges encountered and future prospects as this technique continues to shape the manufacturing landscape.

- Understanding Factory Seam Duplication for Panels

- Techniques and Technologies Employed in Replication

- Benefits, Challenges, and Future Prospects of Seam Duplication

Understanding Factory Seam Duplication for Panels

Factory seam duplication is a precision technique that plays a vital role in the automotive industry, particularly for manufacturing roof and floor panels. This advanced process ensures that each panel has an identical seam, providing a seamless and structurally sound finish. By duplicating factory seams, manufacturers can achieve a high level of consistency and quality control, ensuring that every vehicle leaving the assembly line meets strict safety and aesthetic standards.

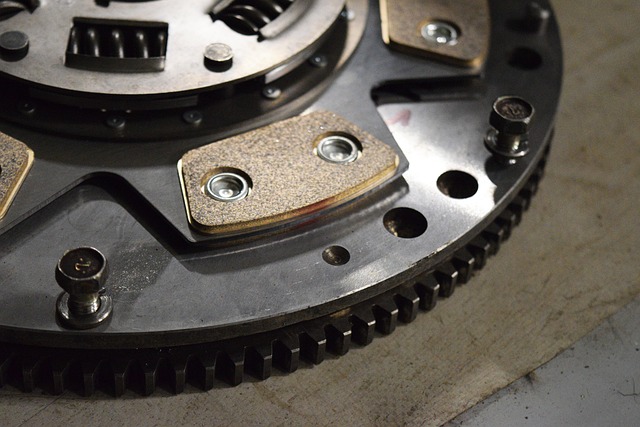

This method involves using specialized equipment and expert knowledge to replicate the original manufacturing process. It’s akin to an artistic touch-up, but on a much larger scale. Just as a painter duplicates a brushstroke for a perfect copy, factory seam duplication experts use advanced tools to match the exact pattern and positioning of seams seen in original panels. This is especially crucial when considering incidents like car collisions or bumper repair, where precision is key to restoring structural integrity and the vehicle’s aesthetic appeal through auto body painting.

Techniques and Technologies Employed in Replication

In the realm of automotive manufacturing and restoration, achieving seamless replication is paramount for both roof and floor panels. Factory seam duplication techniques have evolved significantly, employing advanced technologies to mimic the precision and aesthetics of original parts. Modern auto repair shops and car body restoration specialists utilize a combination of mechanical and digital methods to create exact duplicates.

One such technique involves computer-aided design (CAD) software, which allows for detailed measurements and precise replication of panel contours. This is followed by robotic welding and cutting machines that can replicate the original factory seams with remarkable accuracy. For intricate shapes and curves, laser cutting technology is employed, enabling clean and consistent results. Additionally, advanced painting systems use robotics to ensure uniform color application, matching the exact shade and finish of the original components, be it in an auto frame repair or a complete car body restoration project.

Benefits, Challenges, and Future Prospects of Seam Duplication

Factory seam duplication techniques for roof and floor panels offer numerous benefits to both manufacturers and consumers. By accurately replicating seams, these methods enhance structural integrity, ensuring durable and leak-proof panels. This is particularly advantageous in automotive applications, where water penetration can cause significant damage to vehicle bodywork. Seam duplication also streamlines production processes, reducing manufacturing time and costs associated with manual seam joining. Moreover, it enables consistent quality control, minimizing defects and improving overall product reliability.

However, implementing factory seam duplication faces several challenges. Achieving precise duplication requires advanced machinery and skilled technicians capable of handling intricate details. Additionally, the cost of acquiring specialized equipment can be substantial, posing a barrier for smaller manufacturers or car repair services looking to integrate these techniques. Furthermore, ensuring seamless integration of duplicated seams with existing panel designs and materials demands careful consideration and extensive testing. Despite these hurdles, future prospects look promising, driven by advancements in technology and growing demand for efficient, cost-effective, and reliable vehicle restoration processes.

Factory seam duplication techniques have revolutionized roof and floor panel manufacturing, offering enhanced structural integrity and aesthetic appeal. By employing advanced technologies, manufacturers can replicate seams with precision, ensuring consistent quality across panels. While challenges remain, particularly in material compatibility and cost, the benefits of seamless duplication bode well for future innovations. As the demand for lightweight, durable, and visually uniform panels grows, factory seam duplication techniques will continue to play a pivotal role in shaping the automotive and construction industries.