Factory seam duplication is a specialized auto body repair process using advanced measuring, cutting, and assembly techniques to precisely replicate original vehicle seams, meeting OEM standards for superior quality, aesthetics, and structural integrity, ensuring customer satisfaction and restoring vehicles to their original condition.

In the realm of manufacturing and repair, achieving OEM-approved quality is paramount. Factory seam duplication emerges as a game-changer, enabling precise replication of original seams for consistent, high-quality repairs. This article delves into the understanding, benefits, and best practices surrounding factory seam duplication techniques. By exploring these methods, folks can ensure repair work that rivals the original, revolutionizing the way we approach OEM standards.

- Understanding Factory Seam Duplication Process

- Benefits of Using Original Equipment Manufacturer (OEM) Approval Techniques

- Best Practices for Achieving Consistent Repair Quality

Understanding Factory Seam Duplication Process

Factory seam duplication is a specialized process that exactingly replicates the original factory seams found on automotive bodies. This advanced technique involves meticulous measuring, precise cutting, and skilled assembly to match the exact specifications set by the vehicle manufacturer. By employing state-of-the-art equipment and adhering to stringent quality control measures, auto body shops equipped with this technology can deliver OEM-approved repair results, ensuring your vehicle retains its original integrity and value.

Whether you’re considering repairs at an auto body shop near me or visiting an auto collision center, understanding the factory seam duplication process is key. This innovative approach bridges the gap between damage and restoration, guaranteeing a seamless (both literally and figuratively) fit that meets the high standards of original equipment manufacturers.

Benefits of Using Original Equipment Manufacturer (OEM) Approval Techniques

Using Original Equipment Manufacturer (OEM) approval techniques for factory seam duplication offers significant advantages in maintaining repair quality standards. By adhering to OEM specifications, auto repair services can ensure that replacement parts precisely match the original equipment in terms of fit, finish, and durability. This level of precision is crucial for not just aesthetics but also structural integrity, ensuring vehicles function optimally after repairs.

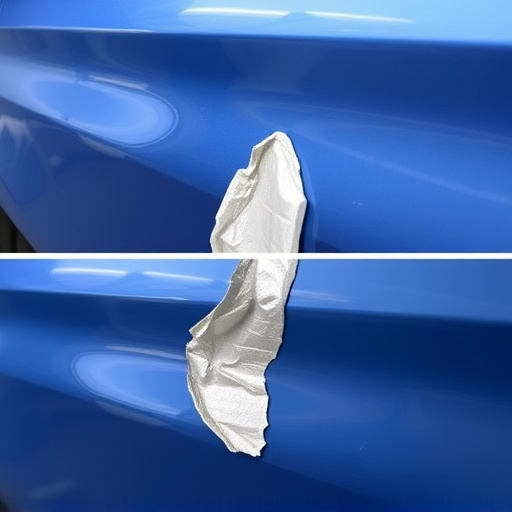

OEM-approved methods, including advanced techniques like paintless dent repair, enable car repair services to avoid common issues associated with generic or poorly made parts. These methods prioritize the use of specialized tools and materials that preserve the vehicle’s original appearance, making them ideal for sophisticated and intricate repair jobs. Consequently, factory seam duplication through OEM approval enhances customer satisfaction and ensures that vehicles meet or exceed their original condition post-repair.

Best Practices for Achieving Consistent Repair Quality

Achieving consistent repair quality in vehicle paint work, especially when dealing with complex shapes and curved surfaces like car bodies, demands meticulous attention to detail. This is where factory seam duplication plays a pivotal role. By utilizing advanced techniques to replicate the original factory seams, car dent removal experts can ensure precise and OEM-approved results. The best practices for this process involve careful preparation of the surface, precise measurement and marking of critical points, and consistent application of specialized tools during the duplication phase.

Regular training sessions for technicians, adherence to standardized procedures, and frequent quality checks are integral parts of maintaining consistency. Using high-quality duplicating equipment and adhering to strict environmental conditions also contribute significantly. These practices not only guarantee flawless vehicle paint repair but also ensure that every car dent removal service meets the highest industry standards, resulting in a seamless and impeccable finish for every car repair shop.

Factory seam duplication is a game-changer in ensuring OEM-approved repair quality. By understanding the process, leveraging its benefits, and adhering to best practices, repair shops can consistently deliver top-tier workmanship. This not only enhances customer satisfaction but also maintains the integrity of the original equipment, making factory seam duplication a vital technique in modern automotive repair.