Factory seam duplication is a critical quality assurance process in manufacturing, especially for auto body work, ensuring structural integrity and aesthetic precision through accurate recreation of seam alignments. Advanced measurement systems capture detailed dimensions and angles, enabling precise adjustments. In collision repair shops, accurate factory seam duplication is vital to restore vehicles to pre-incident condition, maintaining value and integrity. Automated measuring systems streamline workflows, minimizing defects and providing reliable, high-standard services for car scratch repair and auto glass replacement. Manufacturers should adopt a holistic approach combining qualitative and quantitative assessments, utilizing advanced technologies, regular training, standardized work instructions, and visual aids, fostering continuous improvement to optimize the process.

In the manufacturing sector, ensuring consistent quality is paramount, especially in intricate processes like factory seam duplication. This article delves into the critical role of measuring systems in optimizing this fundamental aspect of production. We explore how system measurement enhances efficiency and consistency in fabricating high-quality goods. Additionally, we provide practical strategies for implementing effective metrics to continuously improve factory seam duplication processes, ultimately driving operational excellence.

- Understanding Factory Seam Duplication: The Foundation of Quality Assurance

- How Systems Measurement Enhances Efficiency and Consistency in Fabrication Processes

- Strategies for Implementing Effective Metrics to Monitor and Improve Factory Seam Duplication

Understanding Factory Seam Duplication: The Foundation of Quality Assurance

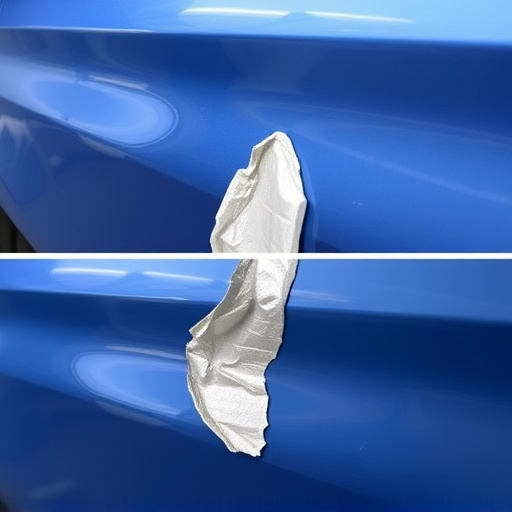

Factory seam duplication is a critical process that forms the backbone of quality assurance in manufacturing, particularly within auto body work and collision repair shops. It involves accurately recreating or duplicating the precise alignment and positioning of seams in various components to ensure structural integrity and aesthetic precision. This meticulous practice is pivotal, especially when dealing with intricate designs and complex assemblies.

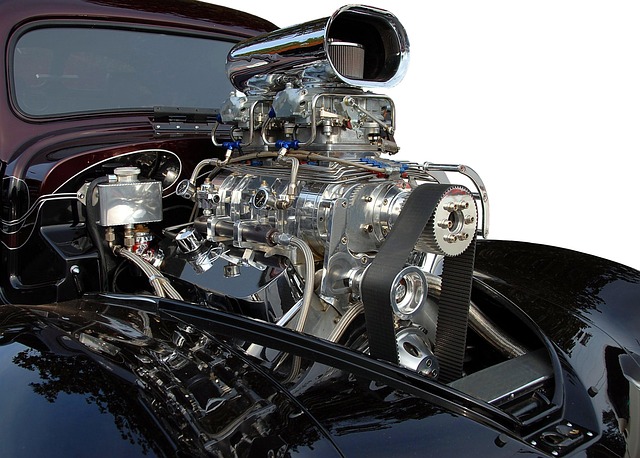

By employing advanced measurement systems, manufacturers can achieve a high degree of accuracy in frame straightening, ensuring that every seam aligns perfectly. These systems capture detailed dimensions and angles, allowing for precise adjustments and repairs. In a collision repair shop, where auto body work demands meticulous attention to detail, accurate factory seam duplication is essential to restore vehicles to their pre-incident condition, maintaining the integrity and value of the vehicle.

How Systems Measurement Enhances Efficiency and Consistency in Fabrication Processes

In the realm of factory seam duplication, systems measurement plays a pivotal role in enhancing both efficiency and consistency across fabrication processes. By employing precise and automated measuring systems, manufacturers can achieve remarkable accuracy when replicating seams on various materials, such as auto body panels or car scratch repair components. This technological advancement ensures that every duplicate is an exact mirror image of the original, minimizing defects and maximizing product quality.

Furthermore, the integration of measurement systems streamlines workflows in auto glass repair and even auto body painting. It enables manufacturers to maintain a standardized approach, guaranteeing repeatable results regardless of who performs the duplication task. This consistency not only reduces waste but also cultivates a seamless experience for clients availing services like car scratch repair or auto glass replacement, knowing that every outcome will be up to the highest standards.

Strategies for Implementing Effective Metrics to Monitor and Improve Factory Seam Duplication

To implement effective metrics for monitoring and improving factory seam duplication, manufacturers should adopt a systematic approach that combines qualitative and quantitative assessments. Begin by establishing clear goals and key performance indicators (KPIs) specific to the process, such as duplication accuracy, cycle time, and defect rates. Utilize advanced technologies like computer-aided measurement systems and digital imaging to capture precise data on seam alignment and consistency. These tools enable real-time feedback, facilitating quick adjustments to duplicate procedures.

Regular training sessions for employees involved in vehicle body repair or auto painting can significantly enhance the quality of seam duplication. Standardized work instructions and visual aids should be provided to ensure consistent techniques across the factory floor. Additionally, implementing a continuous improvement culture encourages workers to identify and suggest improvements based on their experiences, fostering an environment where learning from mistakes is encouraged rather than penalized. This holistic approach leverages technology, training, and teamwork to optimize factory seam duplication processes.

Measuring systems play a pivotal role in ensuring the quality and consistency of factory seam duplication. By implementing effective metrics, manufacturers can enhance efficiency, identify bottlenecks, and continuously improve their fabrication processes. This not only leads to better product outcomes but also ensures customer satisfaction and fosters a competitive edge in the market. Understanding and optimizing these measurements is essential for any facility aiming to excel in the realm of industrial sewing.